Ford Plant Installs Cobots to Optimize Assembly Line for New SUV

Ford Motor Company, one of the global automotive industry giants, has one of its major production sites in Europe located in Craiova, Romania. Recently, Ford deployed cobots on the engine assembly line where they grease camshafts, fill engines with oil and perform quality inspections. The cobots have helped Ford deliver a faster production throughput while also relieving employees of repetitive tasks.

Ford's engine plant in Craiova, Romania

Ford's plant in Craiova, Romania manufactures hundreds of thousands of state-of-the-art Ford engines and vehicles annually, delivered to customers across Europe and beyond. At this plant, Ford manufactures the EcoSport SUV and the 1.01 EcoBoost engine, one of the most award-winning engines in the world. Also, production of a new SUV -- the Ford Puma -- started earlier this year.

The Challenge

Ford Motor Company was looking for solutions to enhance its manual workforce -- generating added value to the manufacturing process.

VIDEO: UR10 Cobots Optimize the Assembly Line at Ford Romania

In doing this, the company realized the need for new automation solutions that could offer space savings, collaborate with people, be moved around when needed, while also providing a high degree of safety and a fast return of investment (ROI).

The Solution

As a result of research and consultations, Ford concluded that the cobots offered by Universal Robots met all the company's needs and criteria.

The intention of installing the cobots was not to replace people but rather help the operators who performed repetitive and challenging tasks.

The Ford Romania plant has now installed four UR10s, the largest of the UR cobot models. Three of them have been integrated directly into work processes and are working alongside the employees on the assembly line, taking over repetitive tasks. One UR10 performs the greasing of the camshaft followers, another fills the engine with oil, and the third checks the engine with a UV light and a camera for leakage after it has been filled with oil.

The camera used in the engine check process is a Cognex camera vision, a UR+ product, communicating with the cobot through Ethernet. The UR10 cobot operates it with the help of an end effector (gripper) specially created and personalized by the Ford engineers according to the application.

The fourth UR10 unit is used for tests and training and will soon have an operational role assigned. Due to the integration of the UR10 into the system that controls the assembly line, the process is simplified. The cobots do not require human/operator's intervention unless a change occurs in the usual processes.

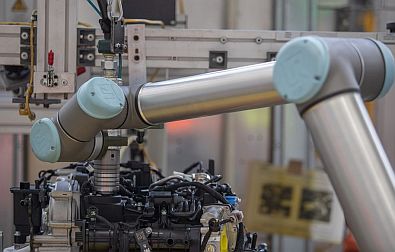

A UR cobot operates the camera for the engine-check process.

"A team from the UK did a global analysis on which type of cobot best suited our needs in the engine and vehicle plants," says Adrian Calangiu, area manager at Ford Romania's engine plant. "When we implemented the cobots, it was not our intention to replace people, we wanted to help the operators that perform repetitive and challenging jobs, having the cobot act as a colleague to the operator instead of as a replacement. The UR cobots have the flexibility to work near the operator, without jeopardizing his safe zone. The collaborative robots also relieve him of monotonous, repetitive tasks giving him the opportunity to contribute in a creative manner.

The UR cobots at the Ford plant were easy to implement. Operators got to know the UR10 cobots quite fast with the help of the Universal Robots Academy online modules that guided them through.

One UR10 performs the greasing of the camshaft followers while another fills the engine with oil.

Collaborative robots offer many opportunities, and the complexity of processes that they can easily accomplish, working side by side with humans, without endangering the work environment, explains Ford's argument for a future long-term collaboration.

"These robots address the applications we are looking for. We really like them due to their small footprint, the ease of implementation, and the fact that they can work alongside our people. We are at the start of our journey with collaborative robots, after our first successful installation, we started looking at installing several more. The more we learn about these robots, the more applications we start to see for them," said Josephine Payne, Engine Plant Manager Ford Romania.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::